Haomei Machinery supplies mobile concrete batching plant concrete mixing plant for Philippines of 25m3, 35m3, 50m3, 60m3 and 75m3. Corresponding models include YHZ25, YHZS35, YHZS50, YHZS60 and YHZS75.

Configuration

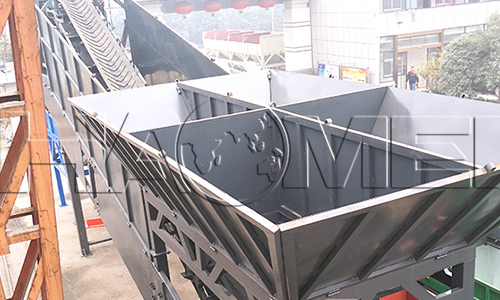

A Haomei mobile batching plant consists of a batching machine, a belt conveyor for aggregates, a cement mixer, a weighing system and a control system. The The cantilever-shaped mixing main engine chassis, the chassis contains the towing pin of the trailer truck and the parking legs; the metering scale of the mixer, cement and water admixture is placed on the chassis; the inspection walking platform, railings, etc. are attached to the periphery. The batching machine is located at the back end of the whole station, the upper part is an aggregate (sand, stone) storage hopper. The belt conveyor frame is a truss structure connecting the main frame and the aggregate batching frame, with a belt frame inside; the main frame, belt frame, and batching frame are combined to form the main structure of the entire mobile concrete mixing plant. The mixing host generally adopts the JS type forced concrete mixer, which can quickly and evenly mix to complete the fluidity and dry hard concrete.

Civil Engineering

A mobile concrete batching plant concrete mixing plant for Philippines needs little civil engineering in comparison with a stationary plant, but the cement silos are still need to be fixed in the ground. In regions where winds are strong, extra civil engineering work might be necessary to fix other units of the plant to avoid possible overturn.

Advantages

The whole station structure reduces the high-strength bolts by 70%, so that the installation is accurate and quick, and the workload is small. All our mobile concrete batching and mixing plants are made of top quality steel that lasts long and has excellent wear resistance. The mixing arm can be used for a long time without being worn. The trailer engine is powerful and energy saving.

Price

The price of mobile batching plants varies from capacity to capacity and configuration to configuration. For example, the ajy50 mobile concrete batching plant price is higher than a mini 25m3 mobile plant, but lower than a 75m3 set. In addition, some devices are optional, such as cement silos, trailers and so on. Therefore, if you need a specific price, you should tell us your practical needs first.

Reprinted from https://www.haomei-machine.com/news/companynews/Philippines-mobile-batching-plant.html