We have equipped two control systems in Haomei Machinery's concrete batching plants: fully automatic concrete batching plant control system, and semi-automatic control system. The existence of these two control systems meets the needs of different customers, but we recommend to use automatic systems, especially with large mixing plants and commercial concrete mixing plants. Why?

The automatic concrete batching plant system makes up for the lack of manual energy. In the peak season of the concrete market, there is a particularly large demand for concrete, which makes the working hours of the mixing plant have to be extended. Sometimes, it even takes 24 hours of uninterrupted production to meet the demand. This requires a high degree of concentration of the staff. With a semi-automatic concrete batching plant, if the workers make mistakes, there will be problems with the quality of the concrete, causing problems such as re-seasoning of the concrete or direct discarding. A fully automatic control system, using centralized microcomputer processing, can effectively monitor the ingredients, under-weighed replenishment, overload alarm, precise measurement, and coordinate the order of each part of the material entering the concrete mixer, ensuring the mixing quality and mixing cycle, so the continuous working capacity of the mixing plant becomes stronger, and the powerful data storage function also ensures that the concrete mixing plant does not make mistakes in the production of concrete with different formulas.

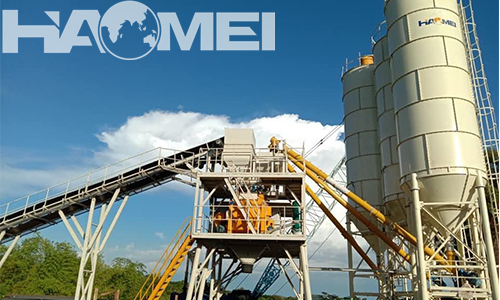

The automatic control of concrete mixing plants would be a development trend in the future. Haomei is among lead yhzs50 mobile concrete batching plant manufacturers and stationary plant suppliers in China. Welcome to contact us at info@haomei.biz for more information!

Reprinted from http://www.batchingplantng.com/haomei-news/Why-should-you-choose-an-automatic-concrete-batching-plant.html